High-Quality

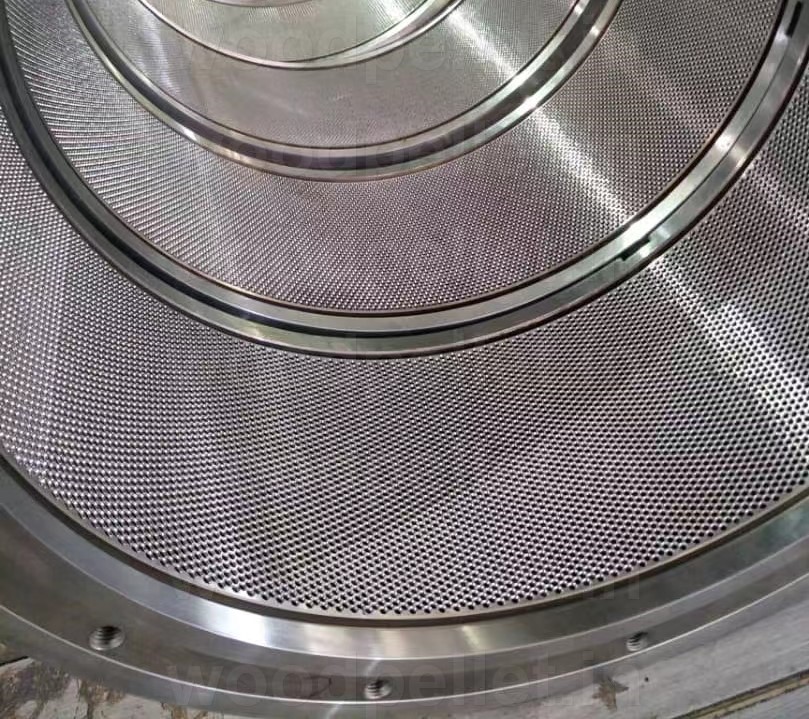

SERVODAY Ring Dies for Pellet Mills

Discover durable and efficient SERVODAY Ring Dies for biomass and wood pellet mills. Customizable solutions for diverse applications. Enhance your production today!

High-Quality Dies for Maximum Efficiency

Optimized performance with SERVODAY Ring Dies for Pellet Mills

SERVODAY Ring Dies are designed to deliver exceptional productivity and high compression ratios, making them the preferred choice for high-density products. These dies are ideal for producing a wide variety of products, including compound feeds, alfalfa, sugar beet, fertilizers, minerals, wood, straw, biomass, and both household and industrial waste.

Superior Strength and Durability

Crafted from forged rings for unparalleled durability with SERVODAY Ring Dies

Manufactured from high-quality forged rings, SERVODAY Ring Dies offer guaranteed strength and longevity. These dies are engineered to withstand the rigors of continuous operation, ensuring reliable performance across various applications. The robust construction of our dies makes them adaptable to all types of products, providing consistent, high-quality output.

Technical Expertise and Customization

Tailored solutions for diverse pelleting needs with SERVODAY Ring Dies

At SERVODAY, we pride ourselves on our technical expertise and ability to provide customized solutions. Our production process includes comprehensive heat treatment to ensure the durability and effectiveness of each die. We cater to a wide range of requests, offering dies with cylindrical, conical, or clamp fittings to meet the specific needs of our customers.

Personalized Service and Support

Dedicated assistance to maximize your production efficiency with SERVODAY Ring Dies

Our sales advisors are committed to providing exceptional service and support. They work closely with users of SERVODAY Ring Dies to ensure optimal performance and productivity. By understanding the unique requirements of each customer, we can offer personalized recommendations on bore type, alloy selection, open surface area percentage, and counterboring type.

Precision Engineering for Improved Performance

Enhance your pellet mill's output with precision-engineered SERVODAY Ring Dies

Several critical factors contribute to the superior performance of SERVODAY Ring Dies. These include precise drilling diameters, optimized compression ratios, strategic hole patterns, and specific types of counterbores. Each factor is meticulously engineered to enhance the efficiency and output of your pellet mill.

High-Grade Steel for Exceptional Hardness

Achieve long-lasting results with durable, high-hardness SERVODAY Ring Dies

SERVODAY Ring Dies are crafted from high-grade steel, ensuring exceptional hardness and durability. The specific hardness level, measured on the Rockwell C scale, is tailored to meet the demanding conditions of pellet production. This ensures that our dies can handle high-pressure operations while maintaining their integrity over time.

Versatile Applications for Diverse Industries

Adaptable solutions for various pelleting applications with SERVODAY Ring Dies

SERVODAY Ring Dies are versatile and suitable for a wide range of industries. Whether you're producing animal feed, biomass pellets, or industrial products, our dies provide reliable and efficient solutions. The adaptability of our dies to different products and production requirements makes them an invaluable asset to any pellet mill operation.

Empowering Global Pellet Production

Extensive Compatibility for Various Pellet Mills

Extensive Compatibility for Various Pellet Mills Our SERVODAY Ring Dies are designed to seamlessly integrate with a wide range of pellet mills, including CPM, Andritz, Buhler, Amandus Kahl, MuNCH-Edelsthl GmbH, Prodesa, Salmatec, La Meccanica, and Buskirk. Leveraging our expertise and advanced manufacturing capabilities, we ensure that our dies meet the exact specifications and compatibility requirements of these renowned pellet mill manufacturers. Whether you operate a CPM, Andritz, or any other pellet mill, you can rely on SERVODAY Ring Dies to deliver consistent performance, exceptional durability, and precise pellet production. With our commitment to quality and compatibility, we empower pellet manufacturers worldwide to achieve optimum efficiency and productivity in their operations.

Superior Craftsmanship for SERVODAY Ring Dies

High-quality materials and precision processes ensure optimal performance for SERVODAY Ring Dies. Starting with rigorously inspected forged steel rings, automated turning shapes each die to meet specific needs with high precision. Advanced drilling with carbide-tipped bits produces polished holes for immediate usability, while tailored counterboring optimizes pellet discharge. Vacuum heat treatment hardens the dies to 53-55 Rockwell C, enhancing wear resistance. Rigorous quality control at every stage guarantees full traceability and top performance, making SERVODAY Ring Dies robust and reliable for high-pressure applications.

High-quality starting materials ensure superior stress resistance for SERVODAY Ring Dies

The manufacturing process for SERVODAY Ring Dies begins with high-quality raw materials, specifically forged steel rings. These rings are chosen for their exceptional stress resistance and are rigorously inspected to ensure they meet our stringent quality standards. By maintaining a large stock of rings, we can guarantee short manufacturing lead times and consistent product availability.

Automated turning processes deliver precision and efficiency for SERVODAY Ring Dies

The turning stage is critical in shaping the SERVODAY Ring Dies to their final form. Utilizing state-of-the-art, fully automated machinery, we can produce any die shape required, ensuring high precision and quality. This automation allows us to maintain swift production times while upholding the highest standards of execution, ensuring that each die meets the specific needs of our customers.

Polished holes ensure immediate usability of SERVODAY Ring Dies

Drilling is a vital part of the SERVODAY Ring Dies manufacturing process. We use carbide-tipped drill bits to produce polished holes, ensuring the die can be used immediately without the need for a running-in period. This advanced drilling technique guarantees smooth hole surfaces, facilitating efficient product flow and minimizing downtime in pellet production.

Tailored counterboring techniques for optimum pellet discharge in SERVODAY Ring Dies

Counterboring is a crucial step in the manufacturing of SERVODAY Ring Dies. This process strengthens the die and ensures proper pellet discharge from the compression hole. Depending on the specific requirements, counterboring can be standard, stepped, conical, or cylindrical. By optimizing the flow rates, this process maximizes the efficiency and lifespan of the dies.

Vacuum heat treatment processes provide exceptional wear resistance for SERVODAY Ring Dies

Heat treatment is essential for achieving the desired hardness and durability of SERVODAY Ring Dies. The dies are hardened to between 53 and 55 Rockwell C, making them more wear-resistant and resilient. The core treatment occurs in a vacuum at temperatures up to 1000°C, a cycle that can take up to 20 hours depending on the load. This meticulous process ensures the dies are robust and capable of handling high-pressure applications.

Ensuring quality and traceability at every manufacturing stage for SERVODAY Ring Dies

Quality control is integral to the manufacturing process of SERVODAY Ring Dies. Inspections are conducted at each stage, with special attention given post-heat treatment. Each die is marked with specific details, including the alloy, hole diameter, thickness, and compression length, ensuring full traceability and adherence to quality standards. This rigorous quality control guarantees that every die we produce meets the highest standards of performance and reliability.

High-Performance Rollers for Enhanced Pellet Production

High-Performance SERVODAY Pellet Mill Rollers for Biomass & Wood Pellets